Slab Track: This railyway runs fast here

Infrastructure

Travel between Delhi and Meerut is now particularly fast: PORR has laid 165 km of the Slab Track Austria System, developed jointly with ÖBB. This makes the new, double-track, 82 km long corridor, with a commercial speed of 160 km/h, the fastest railway line currently in operation in India. This reduces travel time to around one hour.

The Delhi–Meerut RRTS corridor exemplifies next-generation infrastructure in India, combining proven performance, local integration, and international collaboration to enhance regional mobility across the National Capital Region, or NCR. The National Capital Region Transport Corporation (NCRTC), a joint venture between the Government of India and the state governments of Delhi, Haryana, Rajasthan, and Uttar Pradesh has been entrusted with the task of implementing the Regional Rapid Transit System (RRTS) across the National Capital Region (NCR) of India. PORR entered this new market as a system provider and technology partner rather than a traditional contractor, delivering comprehensive technical advisory services, including system integration, technology adaptation for Indian conditions, and support across track design, component specification, quality assurance, and implementation. NCRTC selected PORR’s proven Slab Track Austria system for its superior quality, cost-effectiveness, and fast installation.

Project name: Delhi-Meerut RRTS Corridor

Client: National Capital Region Transport Corporation (NCRTC)

Contractor: PORR Bau GmbH

Architectural/planning office: VCE

Type of contract: Slab Track System provider

Project type: Railway construction, Slab Track Austria (infrastructure/civil engineering)

Scope of work: System delivery Slab Track Austria including technology, planning, training and supervision for the production and construction of 165 km of a new semi-high-speed commuter corridor

Start of construction: December 2019

End of construction: December 2025

Selection of Slab Track technology

To meet the demands of modern high-speed rail, NCRTC selected the PORR Slab Track Austria (STA) system after a thorough evaluation in 2019. The assessment was based on stringent criteria such as:

- Proven track record

- Long design life

- High track quality

- Degree of prefabrication to minimize on-site work

- Local content potential

- Ease of maintenance

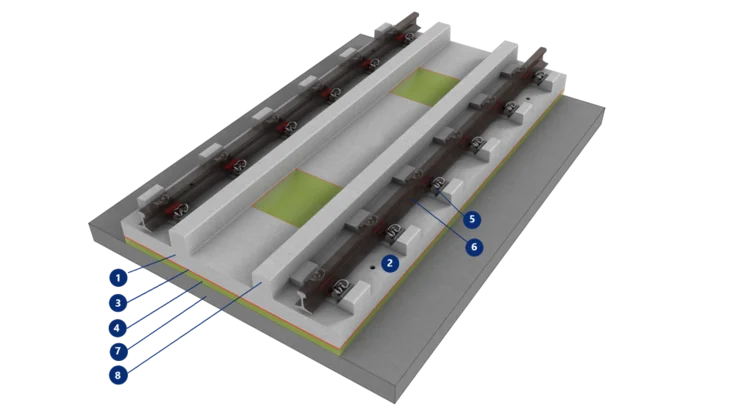

The PORR STA is a modular and adaptable slab track system designed to meet the highest standards of railway construction. It ensures a smoother ride, enhanced durability, and reduced maintenance. The key element is a precast slab track, produced off-site under factory-controlled conditions. This approach enables superior quality and precision of the track, as well as fast installation with less labor and minimal adjustments on-site. which improves the worksite logistics and safety. The PORR precast slabs were used for both the mainline and all of the 135 turnouts, providing system continuity for the entire new line. PORR precast slabs provided added value with the derailment protection integrated in the slab, eliminating the need for installation of the anti-derailment with costly steel rails and the added installation step, thereby saving money and reducing construction time required.

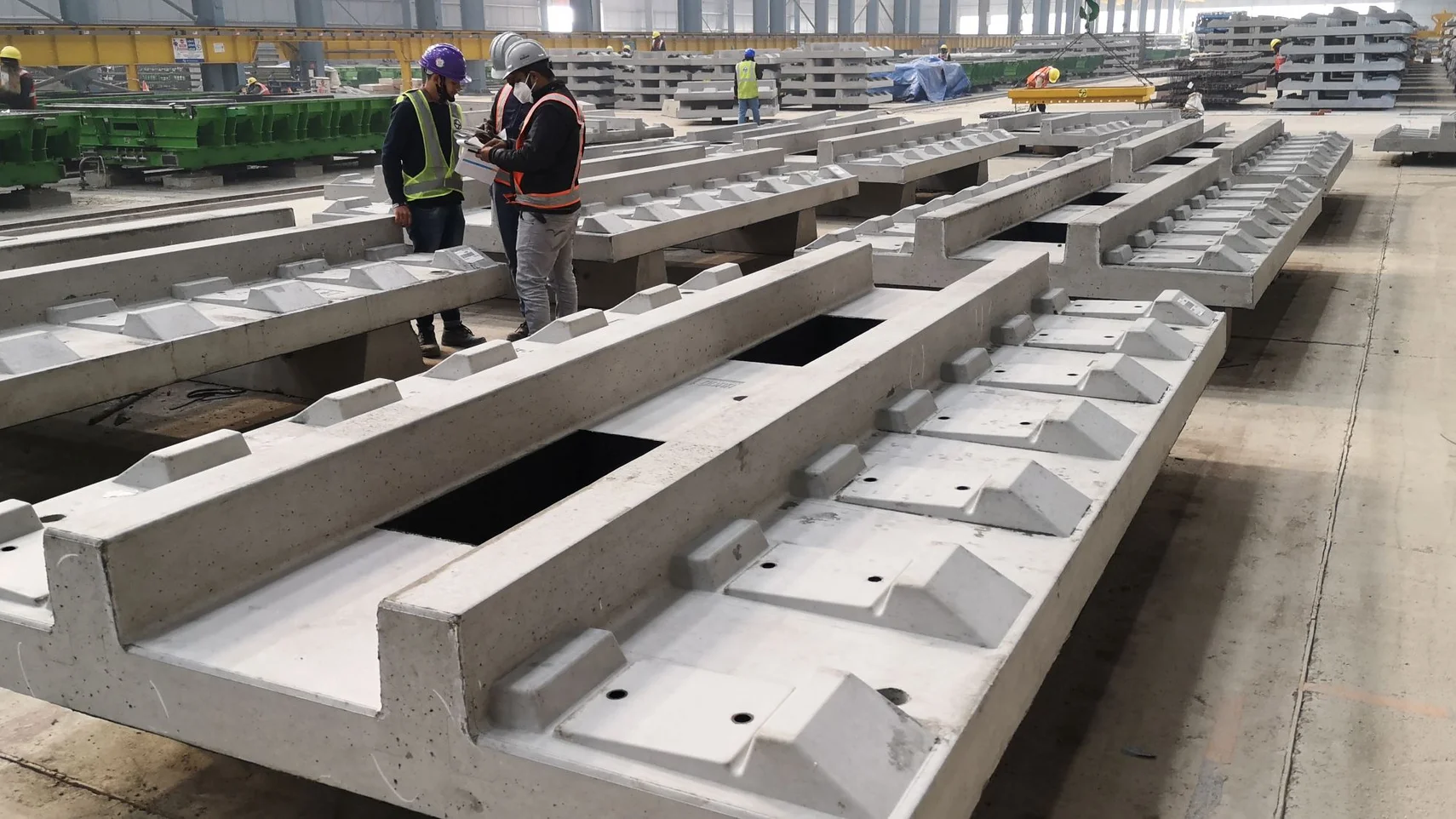

Austrian technology made in India

Following the Made In India approach, under NCRTC management, the local contractors produced and installed the slab track with PORR providing the technology, design, training and supervision which monitored to achieve the required quality and precision. In 2021, Larsen & Toubro, or L&T, was awarded the contract for executing the track works, based on specifications jointly developed by NCRTC and PORR. A central feature of this project was the creation of a dedicated precast slab production facility, an unprecedented initiative in Indian rail construction. Under factory-controlled quality assurance protocols in line with European standards, the precast slabs were produced in an off-site facility with the daily production capacity aligned to project milestones. This manufacturing approach enabled the production of approximately 45,000 slab panels in advance, allowing over 50% of the track works to be executed under controlled factory conditions, significantly improving both speed and consistency. Aligning with NCRTC’s “Make in India” objective, the project emphasized domestic sourcing. PORR collaborated with Indian suppliers for raw materials and components, including steel reinforcement and fastening systems, reducing import dependency and ensuring faster, more flexible delivery schedules.

Given structural and alignment constraints across viaducts, tunnels, and stations, PORR developed several slab track panel configurations with 7, 6, 5, and 4 pairs of support points, as well as specialized panels with integrated maintenance openings for tunnel applications. A highly efficient production process with limited on-site work helped minimize environmental and traffic disruption. The off-site production model also facilitated predictable timelines, reduced rework, and enhanced safety by moving a majority of labour-intensive tasks away from active construction zones.

Installation of Slab Track

Installation of the slab track system began in February 2022 for the 17 km priority section between Sahibabad and Duhai. This segment was selected to demonstrate the system's viability and expedite operations. By late 2023, the priority section was successfully commissioned and is now operating to the full satisfaction of all stakeholders, including NCRTC, contractors, and local authorities.

The remainder of the Delhi–Ghaziabad–Meerut corridor was completed by 2025. It primarily consists of:

- Underground Sections:

- Delhi Side: Anand Vihar Station

- Meerut Side: Meerut Central, Bhaisali, and Begumpul Stations

- Elevated Sections:

- The majority of the corridor runs on elevated viaducts, enabling uninterrupted transit through densely populated urban and suburban areas.

Post-manufacture, the precast slab panels underwent rigorous inspection by NCRTC’s dedicated quality assurance team. They were then either stored at the precast factory or transported to designated logistics and storage sites near the installation zones along the corridor. This decentralized storage strategy ensured timely availability and minimized transport delays during installation.

The installation of PORR STA slab track panels offered significant advantages over traditional track systems commonly used in the Indian railway sector:

- High prefabrication degree—approximately 85% of concrete volume cast off-site resulting in minimal on-site work force requirements. On-site activities are limited to placement and minor SCC (self-compacting concrete) infill—drastically reducing track possession time and disruptions.

- Use of simple gantry cranes for panel installation, enabling quick, safe, and accurate placement.

- On bridge or tunnel sections, only a thin layer of self-compacting concrete (SCC) was needed beneath the slab, eliminating the need for vibration and reducing alignment disturbance risks.

- Local work force teams were swiftly trained in the new installation techniques, achieving installation rates of up to 100 meters per day—a substantial improvement over traditional methods.

Technical data

- 0

Total slab track length in kilometres

- 0

Corridor length in kilometres, double track

- 0

Mainline Slab Track panels

- 0

Turnout Slab Track panels

All done

Given the scale, length, and structural diversity of the Delhi–Meerut RRTS corridor, the installation of the PORR STA slab track system faced several technical and logistical challenges. These were successfully addressed through effective collaboration, engineering adaptability, and continuous innovation.

Training

The PORR Slab Track system demands exceptionally precise construction and the use of installation techniques which were unfamiliar to Indian contractors and work forces at the project start. To bridge the knowledge gap, PORR specialists provided extensive hands-on training to local contractors and workers. This enabled rapid skill development and smooth adaptation of the technology. The system’s intuitive design, combined with structured training programs, allowed local teams to quickly master installation procedures and achieve high productivity.

Interface management

Successful slab track installation depends on the timely and precise completion of viaducts, tunnels, and stations. Delays or deviations in civil works can directly impact the sequencing of slab installation and could lead to increased cost and schedule risk. To manage these dependencies, early planning and a high level of interface coordination with civil and systems contractors was necessary. With support from PORR, the NCRTC team demonstrated strong engineering capacity, and interfaces were managed proactively to avoid major disruptions.

Adaptability in constrained working conditions

Working in densely populated urban areas presented space limitations, access challenges, and heightened safety and environmental considerations. The adaptable PORR STA system proved particularly effective in urban settings due to its high degree of prefabrication—over 85% of the track volume was manufactured off-site. This reduced the need for large quantities of rebar and fresh concrete on-site, significantly minimizing disruption, traffic interference, and environmental impact.

Strict quality and alignment requirements

The PORR STA system provides highly accurate alignment to support high-speed operations. Millimetre-level precision in real-world construction conditions was achieved using advanced survey techniques and strict quality control procedures.

Digital quality assurance

Each slab panel was assigned a unique identification number and tracked through a cloud-based system. This ensured full traceability of concrete properties, embedded components, and fastening systems. The digital QA/QC approach supported rigorous auditing and compliance with international standards throughout the installation process.

Key achievements

The implementation of Phase 1 of the Delhi–Ghaziabad–Meerut RRTS corridor marks a significant milestone in India’s transportation modernization efforts. As the first operational semi-high-speed regional rail system in the country, the project has not only demonstrated technical feasibility but has also set new benchmarks in project delivery, innovation, and stakeholder collaboration.

Despite the project’s complexity and the diverse range of challenges, the PORR Slab Track Austria technology demonstrated a high level of adaptability, reliability, and efficiency. Its modular design, factory-controlled quality, and minimal on-site requirements enabled rapid installation without compromising precision or safety. The successful execution of slab track installation within the planned time and budget underscores the system's suitability for India’s future high-speed and urban rail infrastructure. The system is designed with a long design life (up to 100 years) and low maintenance, reducing lifecycle costs and downtime, a crucial advantage as India builds a scalable, modern high-speed network.