Track and master builder work “Am Spitz”

Infrastructure

Factbox

Client: Wiener Linien GmbH & Co KG

Contractor: PORR Bau GmbH, Abteilung Bahnbau

Contract Type: Gleis- und Baumeisterarbeiten

Project Type: Civil engineering/Infrastructure

Scope: Renovation of the track slabs and rails, including building surfaces

Contract Volume: 1,4 million euros

Construction Start: 07/2018

Construction End: 09/2018

Location: Vienna

In three months of construction, PORR renewed the tram tracks in the area of the intersection plateau “Am Spitz/Brünner Straße/Prager Straße/Schlosshofer Straße.”

The construction work took place in confined spaces while tram services continued to operate. In order to keep traffic disruption during construction to a minimum, the work was divided into four short construction phases.

Background

In recent years, PORR has completed a large number of tramway projects for Wiener Linien. At the end of May 2018, another project with a contract value of EUR 1.4 million was secured. The contract included the renewal of the tracks and switches, the concrete track slab, the surface covering, and two stops at the “Am Spitz” intersection, where three busy roads meet: Brünner Straße, Prager Straße, and Floridsdorfer Hauptstraße. Due to the high volume of traffic, the project was divided into four construction phases lasting two to four weeks. The project was carried out by the Railway Construction, Track Construction EAST department. Minor surface work was carried out by PORR Civil Engineering, Vienna branch.

Complex logistics and various designs

Taxi ranks and bus stops for Wiener Linien, ÖBB and regional transport are located in the immediate vicinity of the junction. The junction is also the only delivery route for many shops. Access to and from the junction therefore had to be guaranteed throughout the construction work. To achieve this, PORR divided the project into several construction phases. At the beginning of each construction phase, roads had to be closed and diversions set up. This work was carried out at night when there was little traffic.

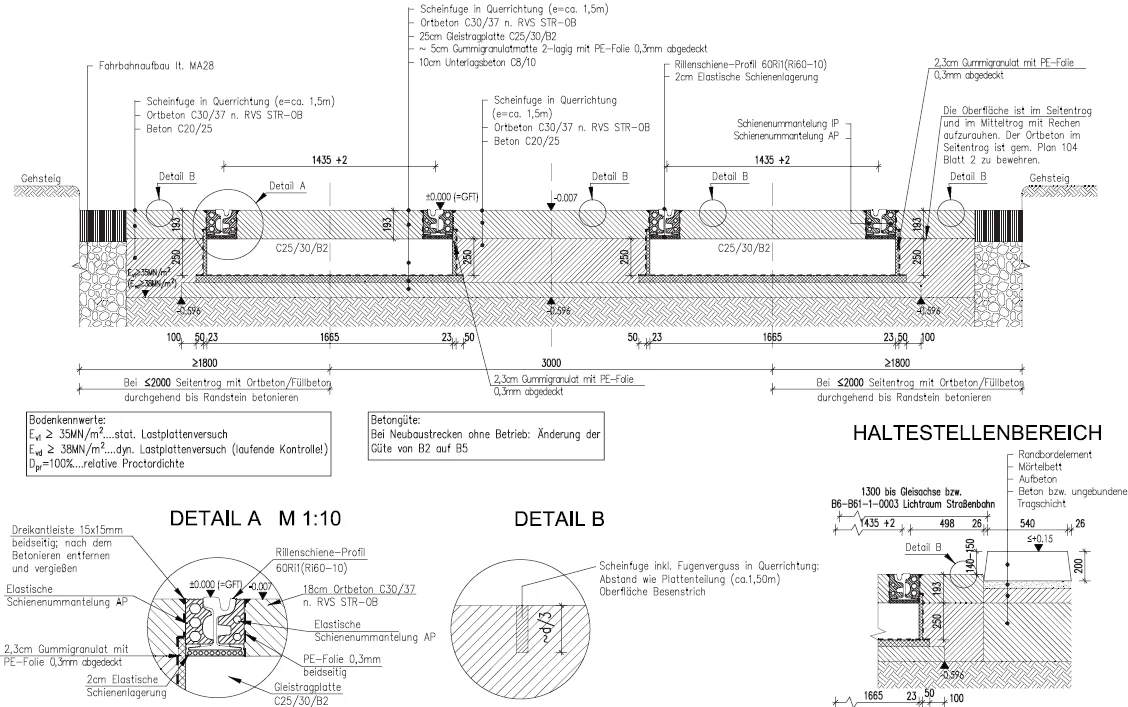

Due to the densely populated project environment, the client specified at the planning stage that the sound-insulated and highly sound-insulated superstructure would be used. With the sound-insulated superstructure, the encased rails are laid on an unreinforced track support slab. The highly sound-insulated superstructure is a lightweight mass-spring system with a thickness of 25 cm. The track base plate, which is reinforced with a reinforcement cage, is separated from the filler concrete at the sides and from the clean layer at the bottom by elastic rubber mats in order to reduce the vibrations caused by the tram.

Due to the project environment, we had to realise two types of construction: a highly insulated and a sound-insulated superstructure.

Site manager PORR Bau GmbH

Construction phase 1the first three weeks

The first phase comprised the northern part of Schlosshofer Straße and the track curve into Brünner Straße. With the exception of the trams, this project area was completely closed to traffic. Even in this phase, PORR worked with both types of superstructure. The straight section in Schlosshofer Strasse was soundproofed and the curve into Brünner Strasse was highly soundproofed. In the first part of the work, the surface between the rails, which consisted of precast concrete slabs, was removed.

In the area of the straights, the existing track support slab was removed with a concrete milling machine as part of the track replacement. The new rails were temporarily supported on wooden sleepers. By supporting the track in this way, tram operation was also possible during the construction work. In the curve, the very time-consuming demolition of the concrete track slab was carried out by an excavator with a hydraulic hammer.

The rails were at the end of their useful life. Special care was required when chiselling to avoid breakage.

Site manager PORR Bau GmbH

Following the demolition work, PORR began constructing the highly sound-insulated superstructure in the curve. Rubber mats were laid on the clean layer and the wooden sleepers were replaced with fixed concrete pads. Following the reinforcement work, the track was aligned in position and height, removed and concreted during the night.

Once the track support slab had been produced, work began on the surface. For this purpose, the rail reveals were closed with chamber filling elements. These elements with a length of 1.5 m enclose the rail on three sides and minimise the vibration caused by the tram. The space in between was filled with road surface concrete after the installation of a reinforcement mat. Due to the limited space available, approx. 85% of the concrete volume used, i.e. around 650 m³, was poured at night between 11 pm and 5 am.

Construction phase 2the challenge

Once the surface concrete had hardened and the asphalt levelling next to the track had been completed, the southern section of Schlosshofer Straße and the eastern half of the Brünner Straße plateau were closed for the second construction phase. This section turned out to be the biggest challenge of the entire project. After all, 180 metres of track, a crossing and a switch had to be renewed. A lot of time was saved by using a concrete milling machine for the demolition in Schlosshofer Straße. The excavator had to be used for the points and the crossing area.

As the condition of the rails at the crossing was at the end of their service life, special care was taken to avoid breaking the rails, which would have resulted in the suspension of tram services. The new points and crossings were assembled in the construction site area prior to installation.

The replacement of the points and crossings, including a 9 metre long track section, was particularly tricky and had to be carried out at night in just 3.5 hours. Using a large mobile crane, the worn old rails were first removed before the new rail sections weighing two to six tonnes, which were stored at the side, could be lifted into place. The rails remained connected with iron fishplates until they were welded together.

A reinforced, highly sound-insulated superstructure was built on 140 m² of sound insulation mats for the switch and the crossing. Due to the crossing rails and the tie rods, which maintain the distance between the rails, the installation of the reinforcement was very demanding. At peak times in the morning and afternoon, a tram crossed the junction every two to three minutes, making it impossible to work continuously. Despite the high tram frequency in this area, the section was opened before the penalised interim deadline

Construction phases 3 & 4the conclusion

In the last two construction phases, the distance to the neighbouring buildings was large enough to switch to the simpler sound-insulated superstructure. In the course of the track replacement, the existing track support slab was milled and concreted after alignment. As the curve from Prager Straße towards "Am Spitz" was very narrow, a lubrication system was installed at the start of each curve in order to minimise the squeaking of the rails in the curve area by means of a lubricating film. There were also two stops in this area that had to be renewed and were therefore closed by Wiener Linien for a fortnight. Once the new kerbs had been laid, the Vienna branch of PORR Tiefbau laid the asphalt surface.

Conclusion

Despite the very hot summer, which placed extreme demands on man and machine, all the work was completed on time and to the client's complete satisfaction.

- 0 m

Track removed and newly laid

- 0 t

Verbauter Betonstahl

- 0 lfm

Rail base profile

Technical data

- Concrete demolition

290 m³

- Concrete milled

190 m³

- Switches replaced

1 Stk.

- Intersections replaced

1 Stk.

- Verbauter Beton

770 m³

- of which road surface concrete as per RVS

290m³

- Filler block elements for grooved rail

2.600 lfm

- Bituminous joint sealant

3.600 lfm