on a high level

Motorway A10 Sebeș – Turda

Romania's national body for motorways and national roads commissioned PORR with the design and construction of a 16.3km section of the Sebeş to Turda motorway.

PORR's tasks included construction not just of the motorway, but also of two motorway rest areas, a road maintenance centre and a motorway junction – plus installation of all utilities, signage and an intelligent transportation system (ITS).

-

EmployerCompania Națională de Administrare a Infrastructurii Rutiere S.A. Romania

-

ContractorARGE aus PORR Construct S.R.L. und PORR Bau GmbH

-

Order typeGeneralunternehmer

-

Project typeInfrastructure, Traffic route construction

-

Project scopePlanning and constructing a new motorway section

-

Order volumeEUR 105 million

-

Construction start05/2014

-

Construction end12/2017

General

Running through the heart of Transylvania, the designed, and now partially complete, Sebeș – Turda motorway doesn’t just create a link between the two cities it’s named for: it also links the A1 motorway with the A3 “Transylvania Motorway”. For construction purposes, this 70km stretch was divided into four sections. An international tendering process was held for Section 4, from which PORR emerged as the best bidder. The contract, involving both the design and construction of this 16.3km-long section, was signed on 23 April 2014.

It was based on the standards established by the International Federation of Consulting Engineers, “Fédération Internationale des Ingénieurs Conseils” (FIDIC), in the “FIDIC 1999 Yellow Book” (Conditions of Contract for Plant and Design-Build). Responsibility for designing and execution lay with the contractor, that was: PORR. The project plans were based on a functional performance description provided by the client. This turnkey construction project is being billed for based on a lump-sum agreement.

Design & build in combination: For this project PORR specialists were required.

Planning stage

In order to create a detailed design for the project, comprehensive soil and topographic surveys were carried out before work began. PORR actually carried out a number of trials on alternative designs while still in the tendering stage, in order to be able to guarantee an optimal price-performance ratio for the motorway construction. This formed a significant element in the selection of PORR as best bidder and winner of the contract for this construction section. The various designs trialled were developed in more detail and formed part of the final design. Altogether, no less than 19,000 plans were created before work could begin.

Approval stage

Given such a large volume of data and plans, it took some time to obtain the necessary approvals. In order to simplify matters with the authorities, PORR divided the project into six sectors. The most difficult sector from a construction point of view – and also the most time-critical – was Sector 5; this was prioritised and thus tackled first. This sector includes a motorway bridge 255m long, a cutting 22m deep, and a diversion to the heavily-used DN1 national road.

Installed utilities

A key challenge with this type of contract is working around the existing utilities. In this case, it was necessary to protect or re-route gas, water, electricity and telephone lines before the main project work could begin. A particularly tricky part of this task was the re-routing of the 220 kV and 110kV overhead lines – made more difficult by the fact that thanks to bureaucratic obstacles, the necessary expropriation on the part of the end client took rather a long time.

Bridge structures

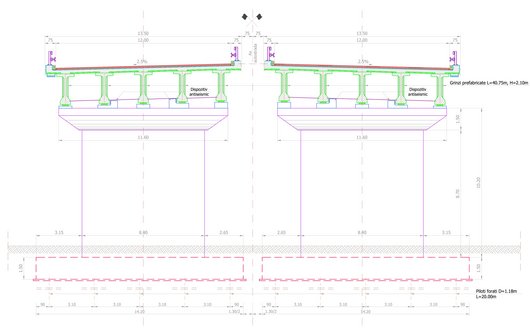

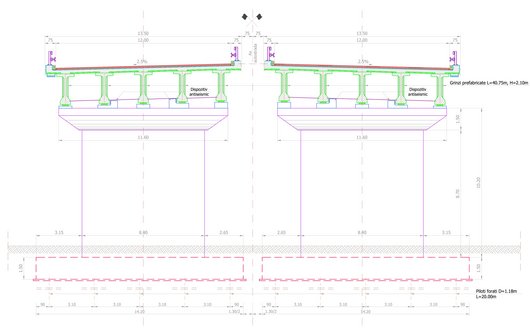

As part of the project, some 30 bridges were constructed, comprising a total length of 1,800m: thirteen motorway bridges, six motorway crossings and eleven bridges in the Turda junction. A further 39 culverts were necessary for the drainage systems and to meet environmental requirements. Due to the geological conditions, the bridges had to be given deep foundations; this was done with bored piles with diameters of 80cm and 118cm. In total, 18,000 metres of piles were installed.

The bridges themselves were constructed with prefabricated beams, as is usual in Romania. Altogether, 244 prefabricated girders of varying lengths – the longest being 40.75m long and 2.10m high – were manufactured in the factory and delivered to the construction site. After lifting the girders, the concrete pre-cast parts were placed and the road surface was laid. A full 65,000m³ of reinforced concrete went into the bridge structures.

Earthworks & Road construction

As with the junction design, numerous trials and tests were carried out for the earthworks while still in the tendering stage, in order to determine whether excavated material from the cuttings could be used for the embankment. Ultimately, there were 3.0 million m³ of excavated material – versus 2.4 million m³ of embankment. Part of the material then had to be further stabilised with cement in order to meet structural requirements.

The road structure comprises a 25cm ballast layer, a 27cm hydraulically-bound base course, a 10cm asphalt base course, a 6cm asphalt binder

layerand a 4cm wearing layer. To build in these large quantities of material without encountering problems, it was necessary to pay considerable attention to the logistics and detailed construction scheduling. Suitable software solutions, such as Primavera and Tilos, were used for construction scheduling and time-position planning. All the asphalt was manufactured by PORR with a Benninghoven TBA 240 U asphalt mixing plant.

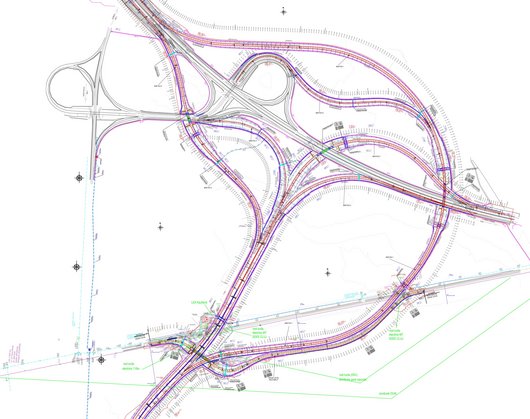

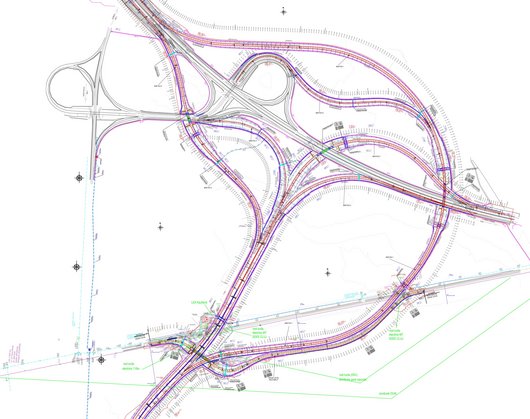

Turda junction

The Turda junction is the centrepiece of the motorway, with its six feeder roads and three new bridges over the A3. The particular challenge here consisted of directly combining these new motorway junctions with an existing junction into the A3 motorway.

In order to guarantee structurally smooth, timely completion, trials of several variant designs were once again carried out.

Drainage

Functioning drainage system is highly important for the longevity of a road. For this reason, a full 100km of surface drainage channels have been installed, as well as 5.6km of longitudinal drainage, 43,000m³ of rock ballast to regulate the streams crossing the route, and 199 oil separators.

Intelligent Transportation Systems – ITS

The contract also included designing and installation of the highly complex monitoring and information system (ITS). This involved installing measurement stations and video monitoring systems, alongside a monitoring centre where the required data will be captured and evaluated. It will then be possible to use the system for real-time monitoring of the weather, road-user speed, and so forth. Deviations from normal

operation – such as traffic jams or accidents – can also be included in an evaluation of the current traffic situation. The information and details derived from the system include factors such as speed reductions for optimising traffic flow, which are transmitted to road users via digital overhead signage, known as traffic guidance systems.

Road maintenance centre and motorway rest areas

A road maintenance centre has been designed and constructed right by the motorway. There are accesses from the motorway itself and from the DN1 national road. The centre includes the monitoring centre, workshops,

storage areas, parking areas, and offices and sleeping areas for maintenance personnel. Two motorway rest areas have also been built.

Technical data

-

Project length16,30km

-

Embankment2.4 million m³

-

Hydraulically-bound base course132.000m³

-

Bored piles18.000m

-

Reinforced concrete6.000t

-

Frost protection material270.000m³

-

Pre-cast bridge girders244 pcs.

Summary

Merely implementing a project of this kind is tough; adding the designing responsibility turns it into a significant challenge for all participants. A team consisting exclusively of PORR employees rose marvellously to the challenge. This was only achievable thanks to a combination of specialists

from every branch – design, bridge construction, earthworks, quality management, contract management, technical administration, project management, etc. This team has successfully completed the motorway on time to meet the highest quality standards.